Timber cladding is such a versatile material to use, as shown in this recent barn conversion project in Lincolnshire carried out by our customers Peter and Jane, who have kindly invited us at Bennetts Timber to have a look around their amazing project.

The project involved the conversion of a traditional farm barn into a single dwelling. In this video, Jane explains their reasons for choosing painted timber cladding as the material of choice for cladding part of the barn conversion:-

Once the decision had been taken to use timber cladding, Peter and Jane came to Bennetts Timber through recommendation and our reputation built up over years for providing quality products at decent prices. We were then able to guide them through the process of choosing the right species of timber, profile and finish for the job.

For this stunning barn conversion project we advised on using Scandinavian softwood with a sawn featheredge finish then coated with a light grey paint which would give a rustic yet chic finish. Feather edge cladding is a traditional timber profile characterised by its overlapping design. Each board is tapered, with one edge thicker than the other, allowing it to overlap the next board below when fitted. This layered arrangement is designed to shed water efficiently, it is therefore particularly well-suited to the British climate!

Feather edge boards are typically sawn rather than planed, giving them a more rustic texture that enhances the natural aesthetic of wood. This makes them ideal for projects where a rural or heritage look is desired.

When the choices were made we then liaised closely with Peter and Jane's chosen contractors, High & Dry Renovations based in the nearby market town of Brigg. We have worked with High & Dry on a number of projects and were able to liaise closely with them on timings and when the cladding would be required during the build process. We also supplied High & Dry with the majority of the other timber required for the conversion process including structural joists, CLS studwork, OSB board, plywood, chipboard flooring sheets, skirtings, architraves together with other planed timbers (PSE) and mouldings.

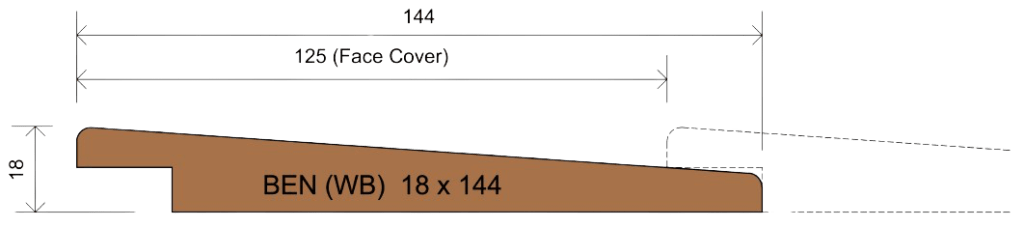

Once the Scandinavian softwood was sourced by our experienced buyer Julie, it arrived in a pack of rectangular planks and was then sent to the mill for sawing, this is where the plank is cut at an angle to make 2 pieces of featheredge timber, in the timber industry that is called 2-ex in that you get 2 pieces of usable timber from a single plank. The featheredge boards were then put through a planer moulder which gives the board a planed back and rebate at the bottom of the board, for ease of fixing, as shown on the profile drawing above. Once machined, the featheredge planks were re-packed and sent to our external painting contractor, J B Timber Importers Ltd, who applied the grey paint in a factory coat finish which gives the timber a stylish finish that contrasts so well with the traditional red brick and tile external finishes.

Each painted featheredge board is then loaded into cradle racks and allowed to air dry, at which point they are carefully re-packed, ready for transport out to site. We liaised with High & Dry regarding a suitable delivery date to fit in with their building schedule. Once on site, the boards were then fixed into place by High & Dry's skilled operatives using stainless stell nails. Always use stainless steel when fixing timber cladding as this ensures any leaching or discolouration is avoided.

We are sure you will agree with us that this is a fantastic project. For further information on timber cladding contact our expert team on 01472 350151 or email at sales@bennettstimber.co.uk